|

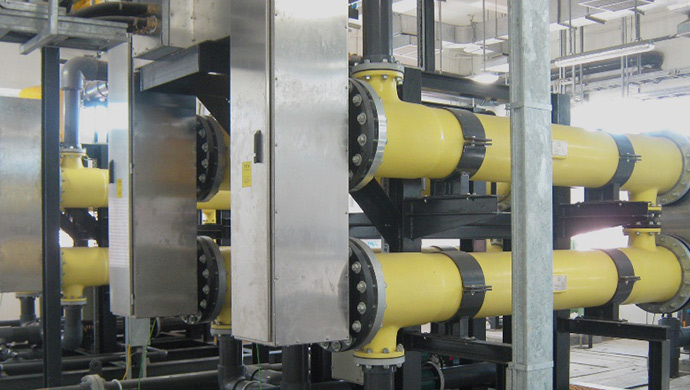

Seawater is used to cool machinery and plant on board all types of marine vessels. It is also used in petro-chemical plants, power stations and other land-based industries, where there is access to the ocean. Although this benefits supplying a free cooling agent, it also causes corrosion and blockage to the cooling water pipeline system. The larvae forms of primary marine life such as barnacles and mussels enter seawater intakes, settle on internal surfaces and develop causing bio-fouling. Where bio-fouling exists corrosion is accelerated even on highly resistant surfaces. The reduced water flow resulting from blocked pipework can cause excessive wear, overheating and inefficiency throughout the system. The growth of marine organisms in sea water systems can result in the blockage of pipework and restrict or completely prevent the use of the systems which incurs significant repair costs to the ship owners. Traditionally, chlorination treatment has been used to remove marine growth by the adding of chloride/ hypochlorite or by electro-chlorination. However these methods have not been satisfactory solutions due to the accelerated corrosion on the structure and unacceptable environment pollution by environmental agencies. |

|

|

Without Anti-fouling System |

|

|

|

|

With electrolytic Anti-fouling System |

The Lerwick Ler-Flow system, which is based on electrolytic copper and aluminum, provides a more reliable, economic and environmental friendly system.

The advantages of using the Ler-Flow Anti Fouling system are:

- Fouling prevention and corrosion mitigation under one system.

- Fully automatic system requiring minimal supervision.

- Low capital investment and installation costs.

- Reduce maintenance costs.

- Increases the life expectancy of pipes and auxiliary equipment.

- Protects major plant parts of the system.

- Environmental friendly and free of pollution.

Power Supply Unit

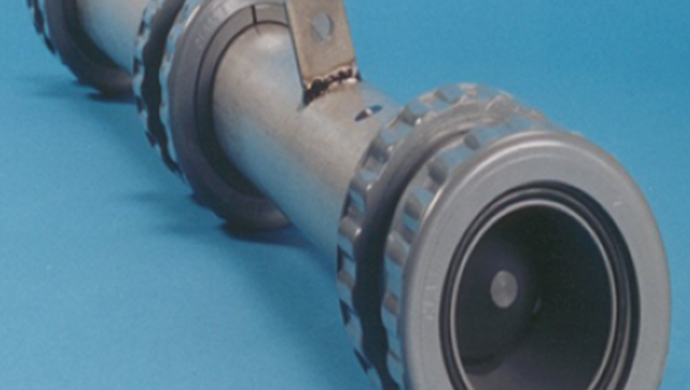

Copper and Aluminum Anodes

Our copper and aluminum anodes come in different standard sizes and lengths. The most commonly used sizes are Ø75mm, Ø82.50mm, Ø102mm and Ø120mm.

|

Diameter (mm) |

Length (mm) |

|||||||

|

Ø75.00 |

250 |

300 |

350 |

400 |

450 |

500 |

550 |

600 |

|

Ø82.50 |

250 |

300 |

350 |

400 |

450 |

500 |

550 |

600 |

|

Ø102.00 |

250 |

300 |

350 |

400 |

450 |

500 |

550 |

600 |

|

Ø120.00 |

250 |

300 |

350 |

400 |

450 |

500 |

550 |

600 |

Working Principle of Ler-Flow MGPS System

The system consists of a controlled power unit, anti-fouling anodes and anti-corrosion anodes. The controller power unit is installed in the ship’s engine room where it can be accessed easily.

One copper anode and one aluminum anode are installed in each sea chest or injection strainer or an intermediate suitable reaction tank. Anode sizes and dimensions vary accordingly to the construction of the sea chest or injection strainer, flow rate and time between dry docking.

Sea life is deterred from settling in environments where the natural level of copper is increased. The electrolytic Ler-Flow system releases a controlled amount of copper ions into the sea water to deter such settlement on pipes and cooler surfaces. The actual concentration of copper ions is extremely small and measured in micro grams per liter of sea water.

Ler-Flow has a fully automated control system supplying D.C current to alloyed anodes installed in the seawater intake or sea chest. It is a dual system, tackling both bio-fouling and corrosion:

a) Copper ions released from the copper alloyed anodes prevent the survival of microscopic marine life which would otherwise foul the cooling system.

b) Ferrous or aluminum ions released from the second ferrous or aluminum alloyed anodes rebuild and repair areas where protective oxides have worn away or are being damaged.

Installation and Maintenance of the Ler-Flow MGPS System

Ler‐Matic's control panel has a modular design feeding a low D.C current to each of the pair of anodes to accurately control the release of materials into the water flow. The control panel has aL.E.D digital display to monitor all the separate anode currents. The system also has the unique feature available of being able to sense a pumping shut‐down and enact 'trickle mode', avoiding overdosing and extending anode life.

Both these designs mean that the optimum level of protection is supplied at all times. The anodes are supplied with sleeves for mounting in a ship's sea chest during dry‐docking. Flange mounted anodes can be installed internally.

Where a system is installed between dry docking we recommend fitting the anodes into the seawater strainers which also makes replacement easier. Control panel parts are designed to be simply 'plug‐in and replace', making the system one of the simplest and most efficient anti‐fouling systems available.

we will contact you within 24 hours.

English

English