Petrochemical

Description

Biological fouling is a frequent issue whenever seawater or freshwater is used as cooling or process water for petrochemical plants processes, and offshore facilities such as oil and gas exploration drilling rigs, FPSO vessels.Several consumers on offshore oil and gas production platforms such as fouling control equipment including Fire Water pipes, Jockey Pump, Cooling Water, and Water Flood.

Milestone Chlorination Technologies is expertise in design, manufacture and supply of special designed skid-mounted complete Seawater ElectroChlorination Unit (Onsite Hypochlorite Generation Package) for safe as well as hazardous area, which could provide effective control of marine fouling in offshore facilities.

Milestone Chlorination Technologies takes advantages of our own designed Parallel Plates Electrolyzer (PPE) and Concentric Tubular Electrolyzer (CTE), which allowed us to provide various solutions for clients to select the best. Concentric Tubular Electrolyzer is using high velocity to achieve self-cleaning technologies, which could save the cost and troublesome from acid washing system and potential hazardous caused by the hydrochloric acid (HCl).

Parallel Plates Electrolyzer with acid washing technology electrochlorination system is able to provide with client the most capital cost effective solution.

Milestone Chlorination Technologies are experienced of the need for systems which operate safely, particularly in offshore facilities. SIL2, SIL3 instrumentation selection, hot redundant PLC programing, hazardous area and safe area is also one of our expertise.

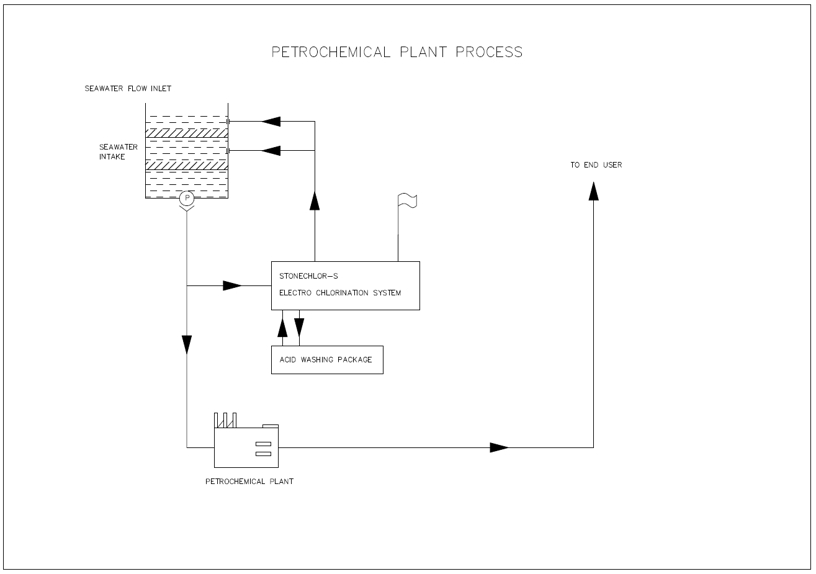

Process Flow

Raw seawater as the battery of the package fed into the package inlet at the designed flow rate, the seawater goes through seawater booster pump and strainer to purify it for downstream usage.The seawater flow rate controlled by the electrical operated valve, certain required flow rate is passed through the electrolytic cell which are fed an electrical supply from the package transformer rectifier.

The rectifier is designed specifically for the requirements of the installed electrolytic cell. It converts the AC platform input voltage into the required low voltage DC current and regulates this output to a selected and controlled level.

Electrolysis process takes place within the electrolytic cell as per the following equation:

At the anode: 2 Cl - 2 e → Cl2

At the cathode: 2 Na+ 2 H2O + 2 e→ 2 NaOH + H2

Overall: 2 NaCl + 2 H2O → 2 NaOCl + 2 H2

Through the electrolysis process the package produces the required amount of sodium hypochlorite together with the by-product, hydrogen gas.

The solution with hydrogen gas are fed into degassing tank and the hydrogen gas will be pushed out by air blowers connected with the storage tank to vent to open atmosphere.

The hydrogen free solution containing sodium hypochlorite is then dosed into the dosing point through dosing pumps or gravity at certain pressure.

English

English