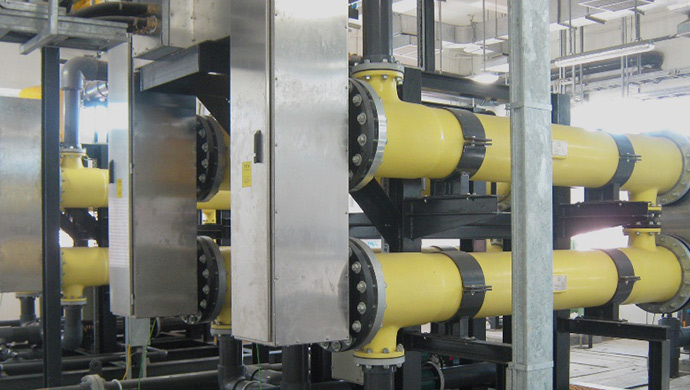

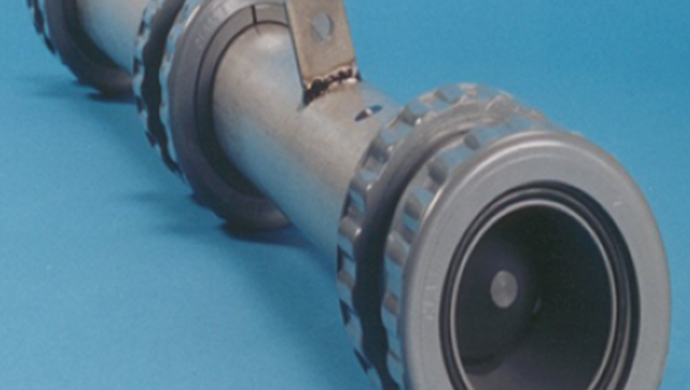

The Tubular Parallel Plate Electrolyzer can be applied in both brine and seawater electro chlorination systems. It is a very effective Disinfection and Biofouling methods for both off-shore and land-based facilities.

The Advantages for Applying Parallel Plate Electrolyzer as Following:

1. Very low operation cost – Milestone Chlorination Technologies designed and developed StoneChlor - B Brine electrolyzer only consume 3.8 Kg Salt to generate 1 Kg Available Chlorine.2. Multi choices on electrolyzer casing - PVC, Acrylic and FRP.

3. Small footprint - Compare to CTE and Mesh type electrolyzer Tubular Parallel Plate Electrolyzer requires less layout footprint to operate.

4. And also the electrolyzer can be put either vertical or horizontal.

5. Good options for power plant and water disinfection application.

6. Require regular acid washing to get rid of the deposit on the surface of the electrodes.

PPE Electrolyzer could be applied in very widely range Electrochlorination system in different types of application.

Technical Design Parameter

|

Electrolyzer Type |

Bipolar Parallel Plate Type |

|

Electrolyzer Casing Material |

PVC, Acrylic, FRP lined with PVC |

|

Parts & Fittings Material |

EPDM, PVC & Titanium |

|

Anodes Material |

Titanium ASTM SB-265 Gr 1 or 2 |

|

Anodes Coating |

MMO, Ru & Ir or Pt. (According to seawater inlet temperature & chloride ion contents) |

|

Cathodes Material |

Titanium ASTM SB-265 Gr 1 or 2 |

|

Cathodes Coating |

N/A |

|

Output Concentration |

1000 to 2000 ppm (Seawater) 8000 ppm +/- 5% |

|

Electrolyzer Design Temperature |

55 Degree Celsius |

|

Electrolyzer Design Pressure |

1.5 to 7 Bar |

Typical Application of Brine (Salt) Electrochlorination:

Typical Application of Seawater Electrochlorination:

we will contact you within 24 hours.

English

English