The Advantages for Applying Concentric Tubular Electrodes (CTE) Electrolyzer as Following:

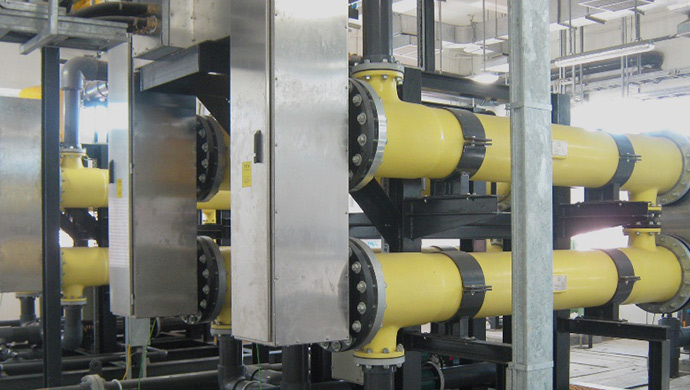

1. Self-Cleaning Technology for Continuous Operation without Acid Cleaning2. Concentric Tube Electrolyzer (CTE) technology for offshore applications or on-shore systems where tubular cells are preferred by customer

3. Bi-polar design with seawater flow through annular region

4. High velocity turbulent flow regime for continuous operation achieving no acid cleaning.

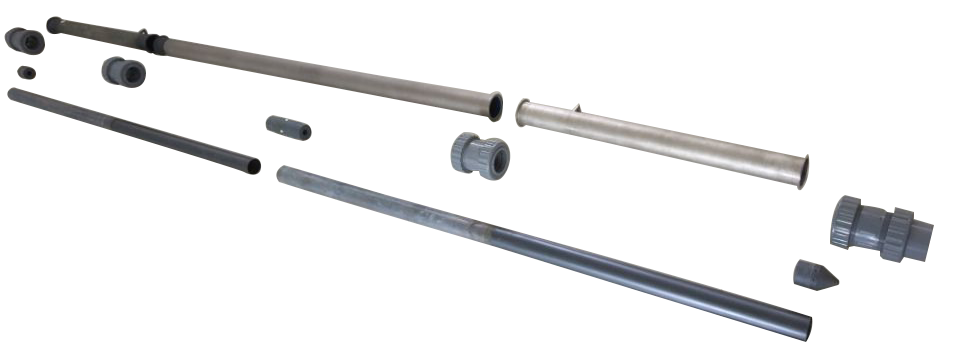

5. Quick and easy maintenance of cell parts

Tubular Chlorine Electrolyzer Technical Design Parameter

|

Electrolyzer Type |

Concentric Tubular Type |

|

Parts & Fittings Material |

ABS (or PVC) EPDM & Titanium |

|

Anodes Tube Material |

Titanium ASTM SB-338 2 |

|

Anodes Tube Coating |

MMO, Ru & Ir or Pt. (According to seawater inlet temperature & chloride ion contents) |

|

Cathodes Tube Material |

Titanium ASTM SB-338 2 |

|

Cathodes Tube Coating |

N/A |

|

Bipolar Tube Material |

Titanium ASTM SB-338 2 |

|

Bipolar Tube Coating |

Half MMO, Ru & Ir or Pt. (According to seawater inlet temperature & chloride ion contents) |

|

Seawater Inlet Flow rate |

> 5 m3 / Hr |

|

Electrolyzer Design Temperature |

55 Degree Celsius |

|

Electrolyzer Design Pressure |

8 to 10 Bar |

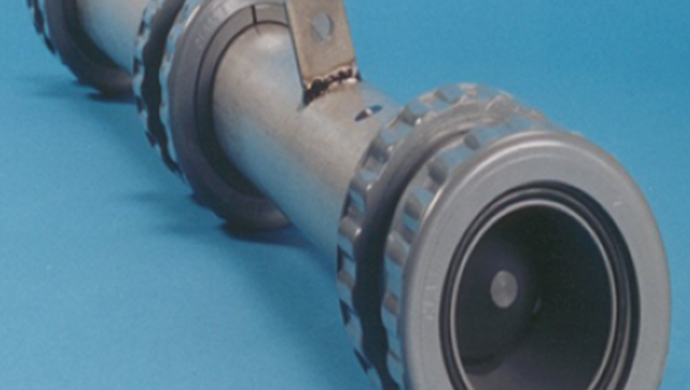

CTE cell consists principally of titanium tubes and connected by plastic joint: inner cell Ti Tube, outer cell Ti Tube or some CTE electrolyzer requires inner cell bipolar and outer cell bipolar besides mentioned above with seawater flowing through the annular space between them. By passing an electric current through the seawater, the sodium chloride contained in the seawater shall be converted to sodium hypochlorite by the electrical chemistry reaction in the chamber.

The CTE Electrolyzer can only be applied in Seawater electrochlorination systems for Land based and marine application.

Typical Application of Seawater Electrochlorination:

we will contact you within 24 hours.

English

English