Together with Lerwick Corrosion Technologies Pte. Ltd. in Singapore, we provide Cathodic Protection Solutions.

The external hull of the ship is usually protected by means of paint coatings. The protective paint coating, however, is easily damaged in localized areas by mechanical action such as anchors chain and by erosion of parts of the stern frame and the leading edge of the rudder.

Corrosion also occurs at rivet heads and welds. Cathodic protection can be of value in preventing or greatly reducing corrosion at these areas.

Impressed current cathodic protection systems are widely used to protect the external hulls of large tankers/vessels and bulk carriers which could not be satisfied adequately by sacrificial anode systems. Often Impressed Current Cathodic Protection or ICCP systems are preferred, as they can be easily controlled in the control room.

The main benefits for using the impressed current system are:

Underwater Installation of MMO/Ti anode

Our system uses one or both of two standard types of MMO/Ti anode. The two standard linear anodes may be installed on all types of vessels where anodes are positioned close to the engine room. Our Impressed Current Anode current output ranges from 25 amp to 400 amp.

All hull-mounted anodes need to be surrounded by a dielectric shield to distribute the current evenly across the ships' hull. Low output anodes use either a sheet of glass reinforced resin on steel double plates, or a trowel-on mastic. High output anodes use smaller double plates to attach the anodes and trowel-on mastic for a large dielectric shield.

Impressed current anodes for ships are normally made of mixed metal oxide titanium or platinized titanium in the shape of long wires, flat plates, or elliptical type embedded in resin. These anodes should be constructed so as to minimize the drag during voyages and are often made very slim or flush with the ship's hull.

The disadvantage of the close proximity of the anodes to the hull is that the current distribution is difficult and that the coating close to the anodes may suffer from overprotection and cathodic disbondment. Therefore, dielectric shields should be installed around the hull anodes. The cathodic protection systems (anodes) are normally placed where the largest current demand is expected, i.e. at the bows (anchor damage) and at the stern. On very large ships a separate system may be installed at mid ship if the construction of the vessel allows.

Because of the varying current demand with the ship's speed or trade an automatic potential control system that regulates the current to maintain a constant potential should be used. For this system reference electrodes should be installed on the ship's hull, remote from the anodes. More than one reference electrode per system may be installed as a backup, e.g., at starboard and portside. The preferred type of reference electrode is silver/silver chloride, although some systems use zinc reference cells.

The power unit is the heart of the system. It receives feedback signals from the reference electrode mounted on the hull and automatically controls the anode current output to optimize the potential required to protect the ship's hull.

The potential of the hull, propeller and shaft are measured against the pre-set reference electrodes and fed to the control center which detects the largest variation, i.e. the area of lowest protection. The control center operates on three-phase A.C in order to ensure a balanced load on the generator plant and a smooth D.C output then adjusts the current output in order to provide the optimum level of protection at all times. Under special operational conditions it may be necessary to alter the level at which protection starts, or adjust the maximum current output. The ICCP system has a built in fail-safe on AC and DC and can sustain a full short-circuit on DC without any component damage.

Installation and Maintenance of the Ler-Matic ICCP System

Lerwick has representatives in all the major shipping centres to provide its expertise services.

Our experience and trained engineer is able to carry out the work. For existing vessels hull components can be installed during dry docking and also the electrical components either during the dry docking or subsequently.

External Protection of the Hull

GeneralThe external hull of the ship is usually protected by means of paint coatings. The protective paint coating, however, is easily damaged in localized areas by mechanical action such as anchors chain and by erosion of parts of the stern frame and the leading edge of the rudder.

Corrosion also occurs at rivet heads and welds. Cathodic protection can be of value in preventing or greatly reducing corrosion at these areas.

Impressed current cathodic protection systems are widely used to protect the external hulls of large tankers/vessels and bulk carriers which could not be satisfied adequately by sacrificial anode systems. Often Impressed Current Cathodic Protection or ICCP systems are preferred, as they can be easily controlled in the control room.

The main benefits for using the impressed current system are:

- Longer period between dry dockings.

- Minimum time and reduced for maintenance and operating cost.

- Fully automatic system operation providing optimum hull protection at all times.

- Provides longer design life for hull protection as compared with sacrificial anode systems

- Less anodes required as compared to sacrificial anode system.

Ler-Matic Impressed Current Anodes

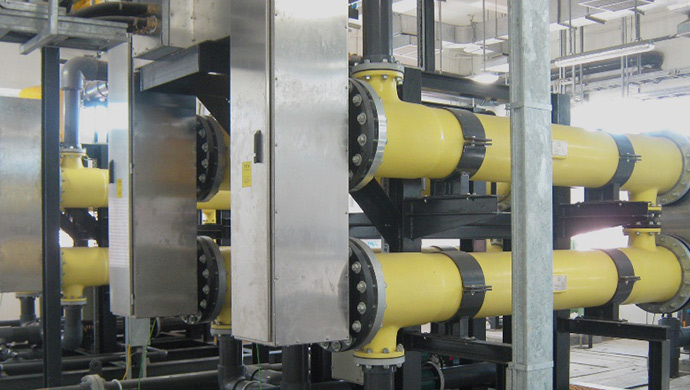

Underwater Installation of MMO/Ti anode

Our system uses one or both of two standard types of MMO/Ti anode. The two standard linear anodes may be installed on all types of vessels where anodes are positioned close to the engine room. Our Impressed Current Anode current output ranges from 25 amp to 400 amp.

All hull-mounted anodes need to be surrounded by a dielectric shield to distribute the current evenly across the ships' hull. Low output anodes use either a sheet of glass reinforced resin on steel double plates, or a trowel-on mastic. High output anodes use smaller double plates to attach the anodes and trowel-on mastic for a large dielectric shield.

Working Principle of Ler-Matic ICCP

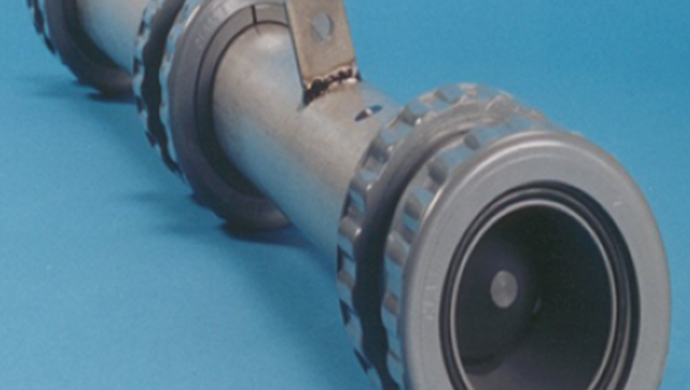

When mains power is available, the required impressed current system can be generated by standard air cooled transformer rectifiers and anodes fixed on the ship's hull through the hull plates.Impressed current anodes for ships are normally made of mixed metal oxide titanium or platinized titanium in the shape of long wires, flat plates, or elliptical type embedded in resin. These anodes should be constructed so as to minimize the drag during voyages and are often made very slim or flush with the ship's hull.

The disadvantage of the close proximity of the anodes to the hull is that the current distribution is difficult and that the coating close to the anodes may suffer from overprotection and cathodic disbondment. Therefore, dielectric shields should be installed around the hull anodes. The cathodic protection systems (anodes) are normally placed where the largest current demand is expected, i.e. at the bows (anchor damage) and at the stern. On very large ships a separate system may be installed at mid ship if the construction of the vessel allows.

Because of the varying current demand with the ship's speed or trade an automatic potential control system that regulates the current to maintain a constant potential should be used. For this system reference electrodes should be installed on the ship's hull, remote from the anodes. More than one reference electrode per system may be installed as a backup, e.g., at starboard and portside. The preferred type of reference electrode is silver/silver chloride, although some systems use zinc reference cells.

The power unit is the heart of the system. It receives feedback signals from the reference electrode mounted on the hull and automatically controls the anode current output to optimize the potential required to protect the ship's hull.

The potential of the hull, propeller and shaft are measured against the pre-set reference electrodes and fed to the control center which detects the largest variation, i.e. the area of lowest protection. The control center operates on three-phase A.C in order to ensure a balanced load on the generator plant and a smooth D.C output then adjusts the current output in order to provide the optimum level of protection at all times. Under special operational conditions it may be necessary to alter the level at which protection starts, or adjust the maximum current output. The ICCP system has a built in fail-safe on AC and DC and can sustain a full short-circuit on DC without any component damage.

Installation and Maintenance of the Ler-Matic ICCP System

Lerwick has representatives in all the major shipping centres to provide its expertise services.

Our experience and trained engineer is able to carry out the work. For existing vessels hull components can be installed during dry docking and also the electrical components either during the dry docking or subsequently.

Linear MMO Anode

|

Zinc Reference Electrode

|

Elliptical MMO Anode

|

Circular MMO Anode

|

Power Unit

|

|

Leave a Message

Email Us

we will contact you within 24 hours.

English

English